Scientific Research Institute for New Chemical Technologies and Materials

Директор НИИ

Калугин Сергей Николаевич

Тел.:+7-(727)-261-25-13; 8-777-258-67-51

e-mail: kalugin_sn@mail.ru

HISTORY OF CREATION AND DEVELOPMENT OF SCIENTIFIC RESEARCH INSTITUTE OF NEW CHEMICAL TECHNOLOGIES AND MATERIALS

The SRINCT&M is organised 13.04.1992 by the decision #4 of the Cabinet of Ministers. The SRINCT&M is reorganized in the Affiliated state enterprise “Scientific research institute of new chemical technologies and materials” of the Republican state enterprise “Kazakh National university named for al-Farabi” of the Ministry of education and science of the Republic of Kazakhstan in accordance with the resolution of the Government of the Republic of Kazakhstan №984 from September, 6th, 2002, “Questions of the Republican state enterprise “The Kazakh National university named for al-Farabi” of the Ministry of Education and Science of the Republic of Kazakhstan”. The basic kind of the institute's activity is the development of theoretical and practical bases of new ecologically clean chemical technologies and materials in Kazakhstan.

The institute unites experimental bases of 7 chairs of the chemical faculty. The experimental-industrial base of the institute is situated on the Joint-stock company "Machine-building factory", the professional training is performed on chairs of the chemical faculty. 2 specialized councils for defence of doctoral and candidate's dissertations are created and operate.

3 academicians of NAS RK, 2 corresponding member of NAS RK, 27 doctors of sciences and 43 candidates of sciences comprised the scientific potential at different times. The institute is completed by not only chemists-researchers on various specialities, but also by engineers, technologists, experts in chemical processes modelling.

The director of institute from the foundation through 2009 was academician of NAS RK, doctor of technical sciences, professor, laureate of the "Kurmet" order Zhubanov Kair Akhmetovich. Doctor of Chemistry Kalugin Sergey Nikolaevich is nominated acting director of SRINCT&M since 2010.

High scientific potential of the institute has allowed to form, substantiate and win the tender for pursuance of three republican target scientific-technical programs, three programs of fundamental researches in which the SRINCT&M was admitted as heading organization by the decision of the Cabinet of Ministry, Ministry of education and science and the Ministry of energy and mineral resources of the Republic of Kazakhstan.

In the light of integration with a high school science in the SRINCT&M the bachelors and candidates for a master's degree of the chemical faculty of the KazNU named for al-Farabi carried out and have successfully defended course and graduation works on materials of the researches executed within the framework of programs.

In consequence of the fundamental researches programs performance following results have been received:

For the first time usage of low- and high-molecular surfactants composition with a glance to character of their interaction on border of phases parcelling is carried out for reception of direct and revertive emulsions water – petroleum, petroleum product.

The new methods of reception of depressor additives to diesel fuels are developed.

The general regularities of formation of well bore colmatation zone, their formation process accelerating or decelerating factors, permeability degree of well bore zone in the functional dependence from colmataging elements passing through them are established.

The new composition including both a technogenic pullback of production and a synthesised product, evinced very high protective properties at steel corrosion in hydrogen sulfide-containing environment is created. The speed decrease of two connested processes of corrosion and hydrogen pickup is observed.

The original methods of reception of the fine-grained nickel with various additives which allow to regulate structural and acid properties of catalysts and to receive on their basis highly active and selective bifunctional catalysts of n-alkanes isomerizating are developed. The received catalysts on the properties surpass ones known from the patent literature.

The catalytical systems from natural components – the Kazakhstan clays zeolites accomplishing cracking of masout with high degree of its conversion to easy gasoil are developed for the first time. The optimum composition of composites and the conditions of activation of components of the catalysts showing maximum cracking activity in relation to high-sulfur masout are defined. There are no analogues in the world scientific and technical literature on catalytical systems from natural feedstock for cracking process of heavy oil fractions without their preliminary desulphurization and bituminous-asphaltenic compounds removal.

The n-paraffine hydrocarbons isomerizating process on the basis of modified natural alumosilicates of the Kazakhstan is investigated and optimised for the first time. The influence of modifying additives (Ni, Co, Cr, Fe, Cu) nature on the composition of n-octane and the Kumkol deposit petroleum straight-run gasoline conversion products in the presence of natural alumosilicates is shown.

The modified sulphated zirconia catalysts applied on the Al2O3 and natural zeolite synthesis method allowing to receive effective alkylation catalysts is offered for the first time. The values intervals of alkylation catalysts synthesis and the regeneration key parametres are defined.

The physical and chemical properties and thermodynamic characteristics of the Republic of Kazakhstan brown coals are defined and their aptitude for the hydrogenization process are analysed.

The scientific bases of production of catalysts for high-quality motor fuel two-stage deriving from the coals of the Karazhyra deposit are developed for the first time. The process spend at low pressure (3-4 MPa).

The compositions and technique of the preparation of new second to none composit electrodes for the reduction of the nitrobenzene are defined.

The catalytical activity of the homogeneous systems on the basis of Pd, Co, Ni, Rh phosphinic complexes in the reactions of olefins carbonylation by carbon oxides and the alcohols and aromatic compounds carboxylation by the alkaline salts of coal acid monoethers are investigated.

Various polymeric compositions with antiseptics and anesthetics for treatment of extensive wounds and burns, and also the injection form of hydrogel implant for the contour plastics was developed on the basis of new water-swellable polymers of the glycol vinyl esters received formerly. High efficiency of the developed hydrophilous medical compositions is educed as the result of the spent medical and biological tests. In particular, it is shown that they possess high antimicrobic activity, sorb the exudate actively, do not impede oxygen penetration into a wound, prevent hypergranulation in consequence of which the wound accelerated abstersion and epulosis is provided. The development of the medical-technical specifications on hydrogel drainages for the surgical treatment of phlegmons and abscesses of soft parts in ophthalmology is finished.

The deformation of copolymers in constant electric field (EF) at the perpendicular orientation of the sample relatively to EF direction is studied. The analysis of the influence of ionogenic groups concentration, рН and ionic strength of the environment, electric current density on the size and speed of the deformation confirms the proposition stated earlier about the electrostatic nature of the polyampholyte hydrogels deformation under the influence of electric field. It is established that it can occur not only in the weakly charged samples, but also in the completely ionized gels. The necessary condition for the occurrence of conversed deformation is the surplus in comparison with gel concentration of low-molecular ions in a solution. The mechanism of the return deformation based on the retarded diffusion of the low-molecular ions charged similarly with a polymer is offered.

The polymeric hydrogels capable to sorb metal ions both in cationic and in anionic forms depending on type of ligand groups and properties of the external environment are received. It is established that the hydrogels on the basis of the monoethanolamine vinyl ester copolymers have a number of advantages in comparison with the ion-exchange tar AM-2B used traditionally in practice in the extraction of precious metals from water solutions. At that the main advantage is that they are produced on the basis of the feedstock producible in the Kazakhstan and can quite replace the sorbent АМ-2B in the technology of the precious metals extraction at the gold-mining enterprises of the Republic.

The polymeric hydrogels on the basis of the SVEMEA are tested at the concentrating of the solutions of heap leaching of gold from various genetic and industrial types of ores of the following deposits: Baktayskoe, Varvarinskoe, Vasil'kovskoe, Dzherek, Komarovskoe, Maralikha, Mizek, Miyaly, Suzdal'skoe, Akkarginskoe, Tokhtarovskoe, Elevatornoe. The sorption technology of the industrial gold-containing solutions processing is performed on the same installations as traditional – with the usage of the АМ-2B that excludes additional expenses for the equipment at the application of the poly-VEMEA.

The complete set of project-constructive documentation for the coal-gas-oil-chemical complex creation is developed as the result of performance of scientific and technical target programs.

Surface-active substances, flotation reagents, extractants for metallurgy, solvents, sorbents, medicinal substances, chemical affinities for agriculture, monomers for polymers, bituminous mastics etc. can be received as a result.

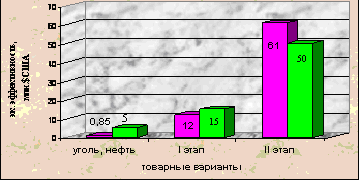

The technical and economic significatives of the first and second stages show (fig. 1) that economic effect in amounts of 12 million US dollars for coal and 15 million for petroleum per year will be reached as the result of the creation of petrochemical production of the mentioned productivity.

The sale of license on this technology to interested firms is supposed. The creation of large coal-gas-oil-chemical complexes in the Kazakhstan is possible on the deposits of brown coal: Karazhyra, Mamyt, Shubarkul, Kenderlyk, Kijakty etc.

The SRINCT&M works in the field of coal processing have attract the attention of foreign investors. In accordance with the Agreement between the Government of the Republic of Kazakhstan and the Government of the Chinese National Republic about scientific and technical collaboration and the Contract on technical collaboration between the Scientific research institute of new chemical technologies and materials and Heilongjiang province hit science and technology cooperation of China-Russia Co. Ltd the SRINCTM has developed, made and started the pilot stand on coal liquefaction with the productivity 50 kg of coal per day, has developed and presented to the customer the explanatory note of production project of building of the coal-gas-oil-chemical complex with the productivity 30000 tons of coal in year, calculations and drafts of the gas-masout furnace, computer program for the calculation of the atmospheric rectifying column, drafts of the rectifying column, the complete set of drafts of the coal and coal paste preparation block. Calculations of the reactors and other equipment for the coal liquefaction block working at the high temperature and pressure is finished.

Figure 1

The project-constructive and technical specification for 36 manufactures is prepared on the basis of actualization of complex scientific researches and project works. The technologies offered to implementation provide depth of the petroleum and coal refining not less than 90-95%.

Now in the Aktobe the National Company "Batys" conjunctly with the Akimat of Aktyubinsk region takes measures for getting the license for coal mining and processing and the creation of coal-gas-oil-chemical complex on the petroleum, gas and coal working with the productivity 100 thousand tons of feedstock per year on the Mamyt coalfield. In the future the complex will become the experimental base for the implementation of new technologies in the field of hydrocarbonic feedstock deep processing and petrochemistry.

The basic and auxiliary equipment for the coal-gas-oil-chemical complex is developed and made: two coal liquefaction reactors with the working pressure 160 atm and working temperature 450°С, installation for the atmospheric rectification of coaly or crude petroleum, installation for the vacuum distillation of heavy gasoil, installation for the catalytical cracking of vacuum distillate, gas-masout furnace for the heating of coal or crude oil, equipment for the briquette factory, reservoirs for the products of coal and coaly petroleum processing.

SRINCT&M is the acknowledged research centre which carries out fundamental researches in priority for republic directions: processing of hydrocarbonic raw materials; development of new catalysts for various processes, development of nanostructure polymeric compositions of a various directions; development of the scientific bases of innovative technologies of the goods with the increased added value reception on the basis of physical and chemical processing of coals, their products, black oils, natural bitumens, natural, oil and cocurrent gas, synthesis-gas, outgoing gases containing the carbon monoxide, carbon dioxide, biogas and other energy sources.

The novelty and perspectivity consists in usage of the widely developed in the world practice at the present time resonance-wave processes which accomplish the mechanochemical activation (vorticose, mechanical, electric, electrochemical, electromagnetic fields, a sound, ultrasound, radiolysis, plasma) of reagents for the processing of coals, their wastages alongside with the application of traditional methods (hydrogenization, hydrogenolysis, gasification, semicoking and coking, combustion etc.) for the development of the scientific bases of the new technologies of the cocurrent oil and natural gases implication in the processes of alkylation, carboxylation, hydroalkoxycarbonylation, reception of the dimethyl ester, aromatic hydrocarbons, synthesis-gas, nanocarbonic materials; and for the development of the scientific bases of the Kazakhstan brown and stone coal deep processing.

The SRINCT&M is developing the technologies and reagents for the dearomatizing, dehydration, desalination and desulphurization of the hydrocarbons and products of their processing, the technological models, allowing to raise reservoir recovery and completeness of petroleum reserves extraction from deposits; the physical and chemical bases of the creation and reception of the new generation of polyfunctional reagents with a complex action, the technology of their application in the quality of the depressor additives, inhibitors of the asphaltic-resinous-paraffine sedimentations and corrosion, new diaphragm type composite materials perspective for the usage in membrane technologies, polymeric hydrogels with trigger properties on which basis the model of artificial neuron – the system including the nonlinear transformer and the adaptive summator as well as the elements providing distant transfer of electrochemical signals will be created.

The SRINCT&M within the framework of executable works accomplished the cooperation with following countries:

USA, West-Lafayette, Indiana, Purdue University (Prof. Kinam Park); Russia, Moscow, Institute of chemical physics of the Russian Academy of Sciences (prof. Kazanskiy K. S.); Poland, Lodz, Technical University of Lodz, Institute of applied radiation chemistry (prof. Rosiak J. M.); The Great Britain, Glasgow (Doctor I. Uchegbu), University of Strathclyde, Department of Pharmaceutical sciences, within the framework of this collaboration in October, 2002 c.c.s., docent Hutoryanskiy V. V. has come for two-year training in University of Strathclyde; South Korea, Daejeon (Doctor К. D. Park), The Korea Advanced Institute of Science and Technology, department of chemical and biomolecular engineering. Teamworks on creation of macromolecular systems with controllable emanation of medicinal substances; South Korea, Seoul (Doctor S. N. Lee), the Technical innovative research center of biomolecular design; Turkey, Ankara, the Hacettepe University (Prof. O. Guven, doctor M. Sen); Russia, the Moscow State University (Professor A. R. Hohlov); Russia, the A. N. Nesmeyanov Institute of Organoelement Compounds of the Russian Academy of Sciences (d.c.s. L. M. Bronstein); Russia, the Tver State university (professor E. M. Sulman); Russia, Moscow, Water Technologic Center (S. Tkachev); Greece, Crete, Heraklion, the Foundation for Research and Technology (professor S. H. Anastasiadis); Canada, Quebec, Department of Chemistry McGill University (professor A. Eisenberg).